- TEAM

- MMSM

- ORICA

- MARKET

- Underground and Civil Construction

- Mining and Construction

- Underground Mining and Civil Construction

- Surface Mining and Construction

- PRODUCT TYPE

- Eletric Detonators

- Detonating Cord

- Non-Electric Detonators

- Electronic Detonators

- CATEGORY

- Drill & balst

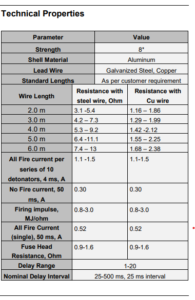

Aluminum Short Delay

Detonators

Detonators

Aluminum Short Delay Detonators are delay elemented caps designed for use in blasting operations.

They feature a cylindrical aluminum shell containing a fuse head, delay composition, priming composition, and a PETN base charge of 8* strength.

These detonators are equipped with either copper lead wires (red & white) or galvanized steel wire (green) insulated with PVC. The design ensures safety and reliability in various applications, including underground metalliferous mines, tunneling, and civil construction projects.

These detonators are equipped with either copper lead wires (red & white) or galvanized steel wire (green) insulated with PVC. The design ensures safety and reliability in various applications, including underground metalliferous mines, tunneling, and civil construction projects.

Aluminum Short Delay Detonators are suitable for use in wet conditions, provided that proper precautions are taken to insulate the lead wire connections. They are robust and tested for continuity and resistance, ensuring reliable performance in the field.

Market: Underground and Civil Constructions

Product Type: Electric Detonators

Download

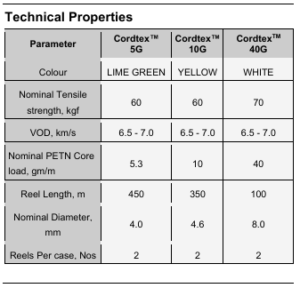

Cordtex™ Detonating Cord

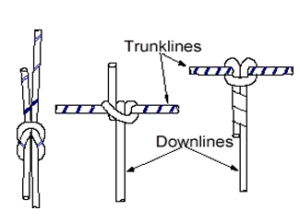

Cordtex™ detonating cord is a strong, flexible detonating cord that consists of a continuous core of PETN powder encased by high-strength textiles and covered by a seamless plastic jacket. It is designed to maintain stability under demanding conditions.

Cordtex™ 5G and 10G are suited for use as surface trunklines, reliably initiating themselves through suitable knots and compatible with Exel™ Millisecond Connectors (MSCs). Cordtex™ 5G can reliably initiate Pentex™ PowerPlus™ boosters, while Cordtex™ 10G is compatible with Pentex™ and Primex™ range of boosters.

Cordtex™ 5G and 10G are suited for use as surface trunklines, reliably initiating themselves through suitable knots and compatible with Exel™ Millisecond Connectors (MSCs). Cordtex™ 5G can reliably initiate Pentex™ PowerPlus™ boosters, while Cordtex™ 10G is compatible with Pentex™ and Primex™ range of boosters.

Cordtex™ 40G has a high core load, making it ideal for applications such as smooth blasting, presplitting, and trimming. The cord should be cut using a single-bladed cutter or a sharp knife on a non-ferrous block to ensure safety.

Cordtex™ detonating cord can be reliably initiated by Exel™ Lead-In-Line, Exel™ Trunkline Delay, or #8 & #6 Strength Electric Detonators. Proper handling and storage are crucial, with a maximum shelf life of 5 years when stored correctly in a cool, dry, well-ventilated magazine.

Market: Mining and Constructions

Product Type: Detonating Cord

Download

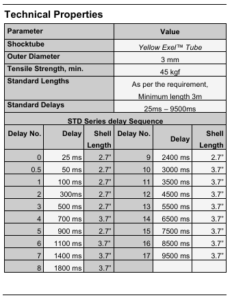

Exel™ STD Detonators

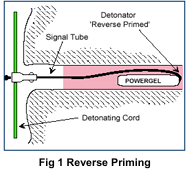

Exel™ STD Detonators are a series of high-strength non-electric detonators designed with various delay intervals between successive firing times. Each detonator consists of a non-electric detonator, a length of Exel™ shock tube, and a J-hook white connector that indicates the delay number.

These detonators incorporate a delay element and a high-strength PETN base charge within an aluminum shell. The shock tube is made of high-strength, abrasion-resistant material that transmits the initiation signal to the detonator. One end of the shock tube is crimped into the detonator shell, while the other end is sealed to ensure waterproofing. The plastic J-hook allows for rapid and secure attachment of the signal tube to detonating cord, and the tangle-free winding configuration is standard across all lengths in the product range.

These detonators incorporate a delay element and a high-strength PETN base charge within an aluminum shell. The shock tube is made of high-strength, abrasion-resistant material that transmits the initiation signal to the detonator. One end of the shock tube is crimped into the detonator shell, while the other end is sealed to ensure waterproofing. The plastic J-hook allows for rapid and secure attachment of the signal tube to detonating cord, and the tangle-free winding configuration is standard across all lengths in the product range.

Exel™ STD Detonators are specifically designed for use inside blastholes in underground mining and civil construction projects. They provide an extended delay series suitable for various applications, including stoping, shaft sinking, tunneling, and drift operations. These detonators are compatible with all cap-sensitive packaged and bulk blasting agents when used with a suitable primer for reliable initiation.

Exel™ STD Detonators are specifically designed for use inside blastholes in underground mining and civil construction projects. They provide an extended delay series suitable for various applications, including stoping, shaft sinking, tunneling, and drift operations. These detonators are compatible with all cap-sensitive packaged and bulk blasting agents when used with a suitable primer for reliable initiation.

Market: Underground Mining and Civil Constructions

Product Type: Non-Electric Detonations

Download

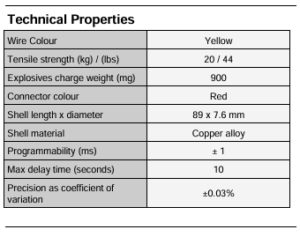

uni tronic™ 600 Electronic Detonator

The uni tronic™ 600 electronic detonator is a cutting-edge product designed for reliable and precise blasting operations. It features a yellow wire with a tensile strength of 20 kg (44 lbs) and an explosive charge weight of 900 mg. The detonator has a red connector and is constructed with a copper alloy shell, measuring 89 mm in length and 7.6 mm in diameter.

The uni tronic™ 600 electronic detonator is a cutting-edge product designed for reliable and precise blasting operations. It features a yellow wire with a tensile strength of 20 kg (44 lbs) and an explosive charge weight of 900 mg. The detonator has a red connector and is constructed with a copper alloy shell, measuring 89 mm in length and 7.6 mm in diameter.

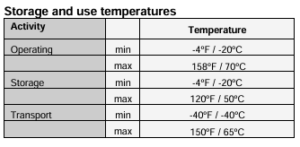

This detonator offers programmability with a precision of ±1 ms and a maximum delay time of 10 seconds, ensuring predictable blasting results with minimal environmental impact. The uni tronic™ 600 is particularly suitable for small and medium open cut coal mines, quarries, and construction applications.

Key benefits include rugged construction for reliable and safe blasting, convenient packaging for efficient operations, and the ability to initiate all boosters reliably due to its full-strength base charge. The recommended maximum sleep time within blastholes is 21 days, depending on ground water conditions.

uni tronic™ 600 detonators must be tested, programmed, and fired using dedicated uni tronic™ equipment.

uni tronic™ 600 detonators must be tested, programmed, and fired using dedicated uni tronic™ equipment.

Proper handling and storage are crucial, with a maximum storage life of up to 5 years in a licensed magazine for Class 1.1B explosives.

Market: Surface Mining & Constructions

Product Type: Electronic Detonators

Download

uni tronic™ 600 Electronic Blasting Equipment

Blasting Equipment

Blasting Equipment

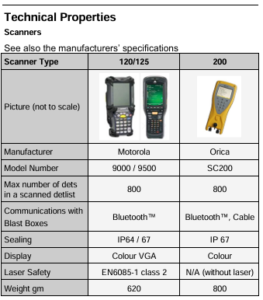

The uni tronic™ 600 Electronic Blasting Equipment comprises a comprehensive suite of devices designed to enhance the precision and reliability of blasting operations. This system includes electronic detonators, test boxes, programming devices, and necessary accessories, all engineered to work seamlessly together.

The core component, the uni tronic™ 600 electronic detonator, is designed for optimal safety and accuracy in initiating blasts. It features programmable delay times, enabling precise timing for sequential blasting to minimize overbreak and environmental impact. The products are built with robust materials to withstand harsh conditions, ensuring dependability in both surface and underground applications.

The uni tronic™ 600 system is user-friendly and utilizes advanced technology to allow for quick testing and verification of detonators through the uni tronic™ 600 Test Box. This enhances operational efficiency by enabling blasting crews to confirm the function of each unit before deployment.

With a focus on safety, reliability, and performance, the uni tronic™ 600 Electronic Blasting Equipment is specially designed for a range of applications, including mining, quarrying, and civil construction projects, ensuring the highest standards in blasting operations.

With a focus on safety, reliability, and performance, the uni tronic™ 600 Electronic Blasting Equipment is specially designed for a range of applications, including mining, quarrying, and civil construction projects, ensuring the highest standards in blasting operations.

Market: Mining and