- TEAM

MMSMC

ROBBINS

- SERVICES

TBM’s Tunnel Boring Machines

- CATEGORY

TBM’s Machines

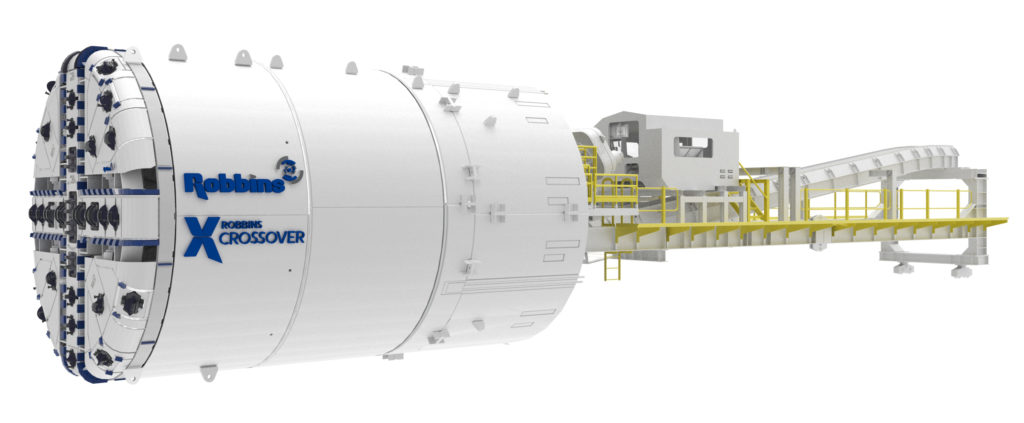

4. Crossover Machines

For the most difficult projects, Robbins Crossover TBMs can offer time-saving and efficient tunneling. Whether the hybrid design converts between EPB and hard rock modes, between Slurry and hard rock, or between EPB and Slurry is up to you. From heavy duty screw conveyors that handle rock to interchangeable cutting tools, Robbins Crossover TBMs are designed to cross between ground conditions that would typically require multiple machines.

What is a Crossover TBM?

A Crossover TBM (Tunnel Boring Machine) is a specialized type of tunneling equipment designed to handle a variety of geological conditions, including both hard rock and soft ground. The Robbins XRE TBM is a prime example of a Crossover TBM, as it incorporates design elements from both Earth Pressure Balance (EPB) machines and hard rock Single Shield machines.