- TEAM

MMSMC

ROBBINS

- SERVICES

TBM’s Tunnel Boring Machines

- CATEGORY

TBM’s Machines

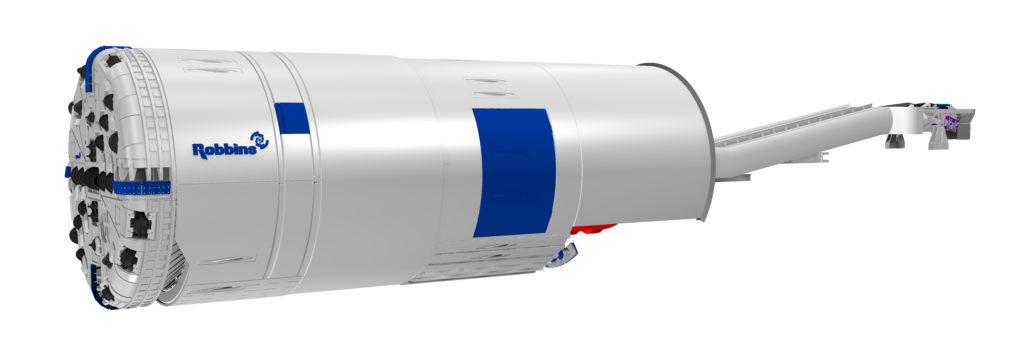

Fractured rock can be an insurmountable obstacle if you buy the wrong machine. Your crew safety and efficiency is at risk, and so is your schedule. With a Robbins Double Shield Tunnel Boring Machine (TBM), your project can have a great safety record and peak performance.

Robbins is no stranger to this type of TBM design. In fact, this is another type of TBM we invented! In 1972 Robbins built the world’s first Double Shield TBM for a customer who anticipated tunneling through large sections of fractured rock. In recent years, several Robbins Double Shield TBMs have broken world records for production.

What is a Double Shield?

A Double Shield TBM consists of a rotating cutterhead mounted to the cutterhead support, followed by three shields: a telescopic shield (a smaller diameter inner shield which slides within the larger outer shield), a gripper shield and a tail shield.

In normal operation (“double shield mode”), the gripper shoes are energized, pushing against the tunnel walls to react the boring forces. The main propel cylinders are then extended to push the cutterhead support and cutterhead forward. The rotating cutterhead cuts the rock. The telescopic shield extends as the machine advances keeping everything in the machine under cover and protected from the ground surrounding it.The gripper shield remains stationary during boring. A segment erector is fixed to the gripper shield allowing pre-cast concrete tunnel lining segments to be erected while the machine is boring. The segments are erected within the safety of the tail shield. It is the Double Shield’s ability to erect the tunnel lining simultaneously with boring that allows it to achieve such high performance rates. The completely enclosed shielded design provides the safe working environment.

If the ground becomes too weak to support the gripper shoe pressure, the machine thrust must be reacted another way. In this situation, the machine can be operated in “single shield mode”. Auxiliary thrust cylinders are located in the gripper shield. In single shield mode they transfer the thrust from the gripper shield to the tunnel lining. Since the thrust is transferred to the tunnel lining, it is not possible to erect the lining simultaneously with boring. In the single shield mode, tunnel boring and tunnel lining erection are sequential operations.

Regardless of the operating mode, working crews remain protected within the shields. Robbins Double Shield TBMs are capable of safely excavating a wide range of geologic conditions on a project. Our Double Shield TBMs are manufactured to suit your project requirements, in diameters from 1.6 m to 15 m (5 to 50 ft).

STANDARD FEATURES ON ALL ROBBINS DOUBLE SHIELD TBMS:

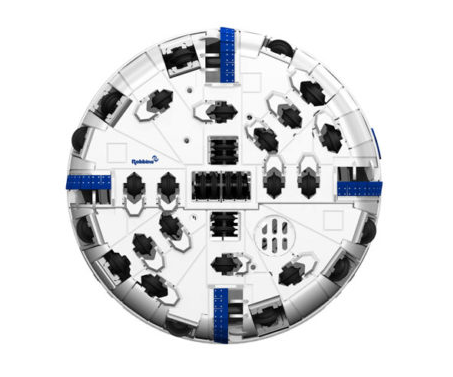

- Flat, low profile cutterhead to enhance face support in broken rock.

- Recessed muck bucket openings with grill bars to prevent ingestion of large rock blocks.

- Back-loading cutters for safe cutter changing in unstable rock conditions.

- Dual thrust-reaction systems, enabling thrust reaction from the tunnel walls or the tunnel lining.

- High-speed segment erector (single- or dual-arm depending on machine diameter) installs pre-cast concrete segments with precision.

- Two-piece articulated telescopic shield offers safety, access to surrounding ground for examination and treatment, and smooth steering through curves.

- Digital guidance system for continuous information on alignment for maintaining strict control of tunnel line and grade.