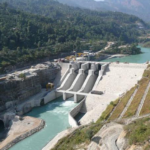

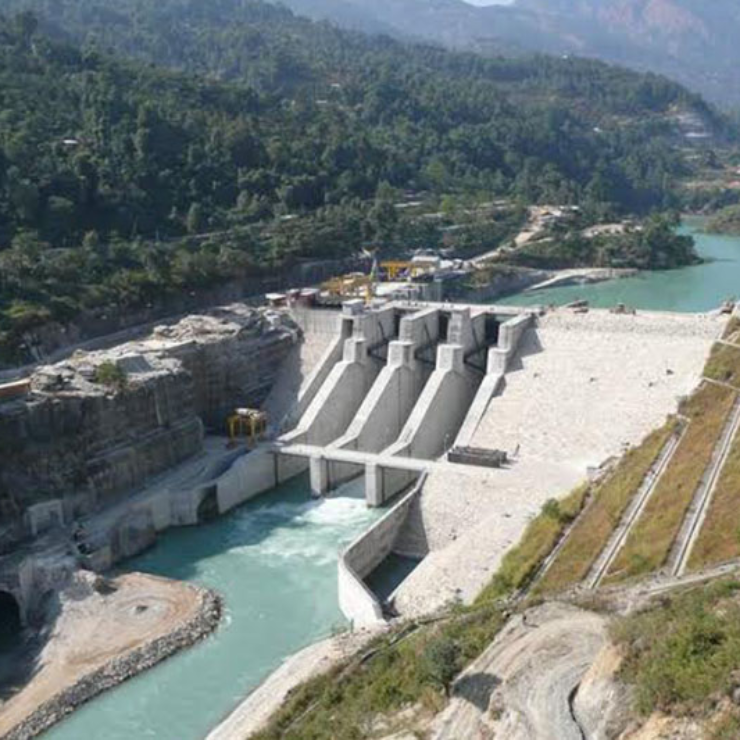

Bheri Babi Diversion Multipurpose Project

- CLIENT

- TEAM

- SERVICES

- CATEGORY

P roject Overview

The Bheri Babai Diversion Multipurpose Project (BBDMP) is one of Nepal’s 11 National Pride Projects. These projects are prioritized plans sanctioned by the Government of Nepal to further develop the mostly rural country. The tunnel irrigates 60,000 (231.7 SM) hectares of land in the southern region of Nepal, and benefits at least 30,000 households. The tunnel also diverts 40 cubic meters (10,567 gal) of water per second from Bheri River to Babai River under a head of 150 m (492.1 ft) using a 15 m (49.2 ft) tall dam, to provide year-round irrigation to the surrounding Banke and Bardai districts. Hydroelectricity is another benefit provided with a generating capacity of 48 MW.

Geology

For this project, the difficult geology of the Siwalik Range, part of the Southern Himalayan Mountains, was much easier than anticipated. The Siwalik Range consists mainly of sandstone, mudstone, and conglomerate. Squeezing ground, rock instability, water inflows and fault zones were also in the mix.

Machine Design

Contractor COVEC Nepal prepared for the challenges associated with tunneling in the tough geology by procuring a custom-designed 5.06 m (16.6 ft) diameter Robbins Double Shield TBM—the first TBM to excavate in Nepal. This TBM bored 12,210 m (40,060 ft) under a mountain range with maximum rock cover of 820 m (2690 ft) and altitude gains of 152 m (499 ft). The machine also had to pass through the Bheri Thrust Zone, a 400 (1312 ft) to 600 m (1969 ft) wide fault which contained clay and water ingress.

Additional features, known as Difficult Ground Solutions (DGS), were built into the design that prevented the machine from becoming stuck while navigating the possible squeezing ground and water ingress:

- Stepped shield: A tapered shield that stepped down to smaller diameters, from the head to the tail, opened the annular gap at the tail of the machine. This allowed for more space around the machine for the ground to contract and lessened the chance of the shield becoming stuck.

- Probe Drilling: By probing drilling in front of the machine, the upcoming ground conditions and water content could be checked. If poor ground was found, grouting could take place to consolidate the zone ahead of the machine. This created a solid plug to bore through. Because high water was planned for, this machine was equipped with several probe drilling locations. 14 ports in the gripper shield at seven degrees were in line with a rear probe on a ring. There were also eight ports in the forward shield at seven degrees that could be drilled by hand. In case of large amounts of water, this array of drilling and grouting gave a full 360 degrees of coverage.

- Shield Lubrication: Although this system was not used, ports were designed radially into the gripper shield that could be used to pump bentonite or other additives to the shield skin to help lubricate the surface and keep the machine moving in squeezing ground.

- Forepoling: Ports were also designed into the forward shield for the option of adding a forepoling drill in the upper forward shield area. This feature would be able to drill holes at 22 degrees, where poles could be inserted into the ground above the machine in an overlapping pattern to stabilize the ground.

Excavation

On October 16, 2017, boring officially commenced. After the initial start-up period, excavation rates exceeded and often doubled the estimated rates. The TBM averaged over 700 m (2,297 ft) per month, with a top excavation rate of 1,202 m (3,944 ft) in one month. Progress was exponential and the project was completed a full year earlier than planned. The ground conditions were better than predictions showed, with 92 percent of the tunnel lined using Type 1 segments (less reinforcement) and only 8 percent of the tunnel requiring more heavily reinforced Type 2 segments. Prior to tunneling predictions stated as much as 26% of the tunnel would require Type 2 segments.

The navigation of the Bheri Thrust Zone was successful. Due to the effective countermeasures taken by the contractor, the fault zone was navigated safely and without delay. The Horizontal Sonic Profile Method (HSP) was introduced to predict geological conditions 100 m (328 ft) ahead of the tunnel face. The prediction results were verified with probe drilling. The TBM passed through the fault zone safely and smoothly within only one week without any challenges.

Excavation Challenges

There were several challenges during excavation, which the crew maneuvered successfully. For instance, on December 27, 2017, large amounts of water began pouring from the 8 o’clock position more than 1 km into tunneling. While the machine advanced the ingress of water shifted to the 11 o’clock position. The contractor thought it was unnecessary to carry out grouting for water plugging, because the section was mainly composed of sandstone and the rock strength was relatively high. However, the method of of slowed excavation, enhanced pumping and drainage, was not sufficient and as inflows intensified back-filling and plugging were adopted.

A second occurrence of high water happened January 6, 2018 a few hundred meters later. Water entered at the 12 o’clock position at an approximate rate of greater than 2000 l/min. The contractor again adopted methods of slow excavation, enhanced pumping and drainage, and intensified back-filling and plugging. The section was in sandstone stratum with excellent stability, and the ingress of water came through fissures in the rock. The determination was there were minimal risks of the TBM being stuck or buried. The resolution was to slowly bore through the water without any drilling or grouting to stop the water.

Not all challenges were water-related; on October 10, 2018 the machine became stuck and could not progress more than 8 km (5 mi) into tunneling. Prior to this stage, the axis of the tunnel was perpendicular to the grain of the rock, a favorable condition for tunneling. However, ground conditions started to change, and the grain became nearly parallel to the tunnel axis. The geological conditions of the tunneling face were soft on the left-hand side and harder on the right-hand side, so the machine alignment became difficult to control. The machine became lodged in place. A high thrust of 18,500 kN (9,517.2 m/s) was exerted and was not able to move the machine. To move the machine, a bypass passage was excavated from the right side of the telescopic section up to the cutterhead. It was cleared out from the 5 o’clock position to the 12 o’clock position. A thrust of 10,000 kN (5,144 m/s) was applied and the machine was able to start boring again. The bypass was completed, and the machine was moving again in just five days.

Just a few meters later at the 8.6 km (5.3 mi) mark the cutterhead became jammed. Loosely cemented sandstone and high-pressure water ingress around the 11 o’clock position triggered an over-break at the left crown area and jammed up the cutterhead. To control the water ingress, 1287 kg (2837 lbs) of polyurethane was injected through a 16 m (52.5 ft) deep probe hole. This almost completely stopped the water. A torque of 440 kNm was then applied to the cutterhead and it was able to become dislodged.

Breakthrough

In April 2019, the Robbins Double Shield TBM defied the astoundingly difficult geology of the Himalayas and broke through about a year ahead of the overall project schedule, and seven months faster than the TBM tunneling schedule.

Various reasons led to the excellent performance at this site. The site staff maintained the machine daily and were extremely vigilant with their cutter changing standards. Logistics were a key to the advance rates being high and the favorable geology with less than expected water in the fault zones led to the success. This project opened the Nepalese tunneling industry for future TBM excavations in Himalayan geology.

Global Gate Way

Just as we’ve found with the truck driver shortage, the impetus behind skilled labor leaving is many-fold. Demographics play a large role—a massive amount of pilots are expected to hang up their hats in the next few years as they reach the mandatory commercial pilot retirement age of 65. And there’s no large group of applicants sitting waiting to replace them. This is likely because it’s becoming considerably more difficult to obtain a pilot license than it was ten years ago. After a 2009 Colgan Air crash, the US Federal Aviation Administration raised the requirements for an ATP certificate from 250 hours to a whopping 1,500 hours.